Asset Management for Construction & Manufacturing

UNIO24 helps construction companies track equipment, tools, and machinery across multiple job sites. Reduce losses, prevent theft, and maximize equipment utilization.

Start for FreeNo credit card required

No Fees

Tools and machinery shouldn’t go missing or break unexpectedly.

UNIO24 keeps everything organized, traceable, and ready to use.

Construction and manufacturing teams work in fast-paced environments with constant movement of tools, vehicles, machines, and materials. Without a centralized system, companies face:

frequent equipment loss or misplacement

poor visibility between sites and storage

unexpected breakdowns and delays

costly over-purchasing

slow inventories and compliance issues

UNIO24 solves these challenges with clear, real-time asset control.

Key Problems UNIO24 Solves

1. Tracking and Movement of Tools & Equipment

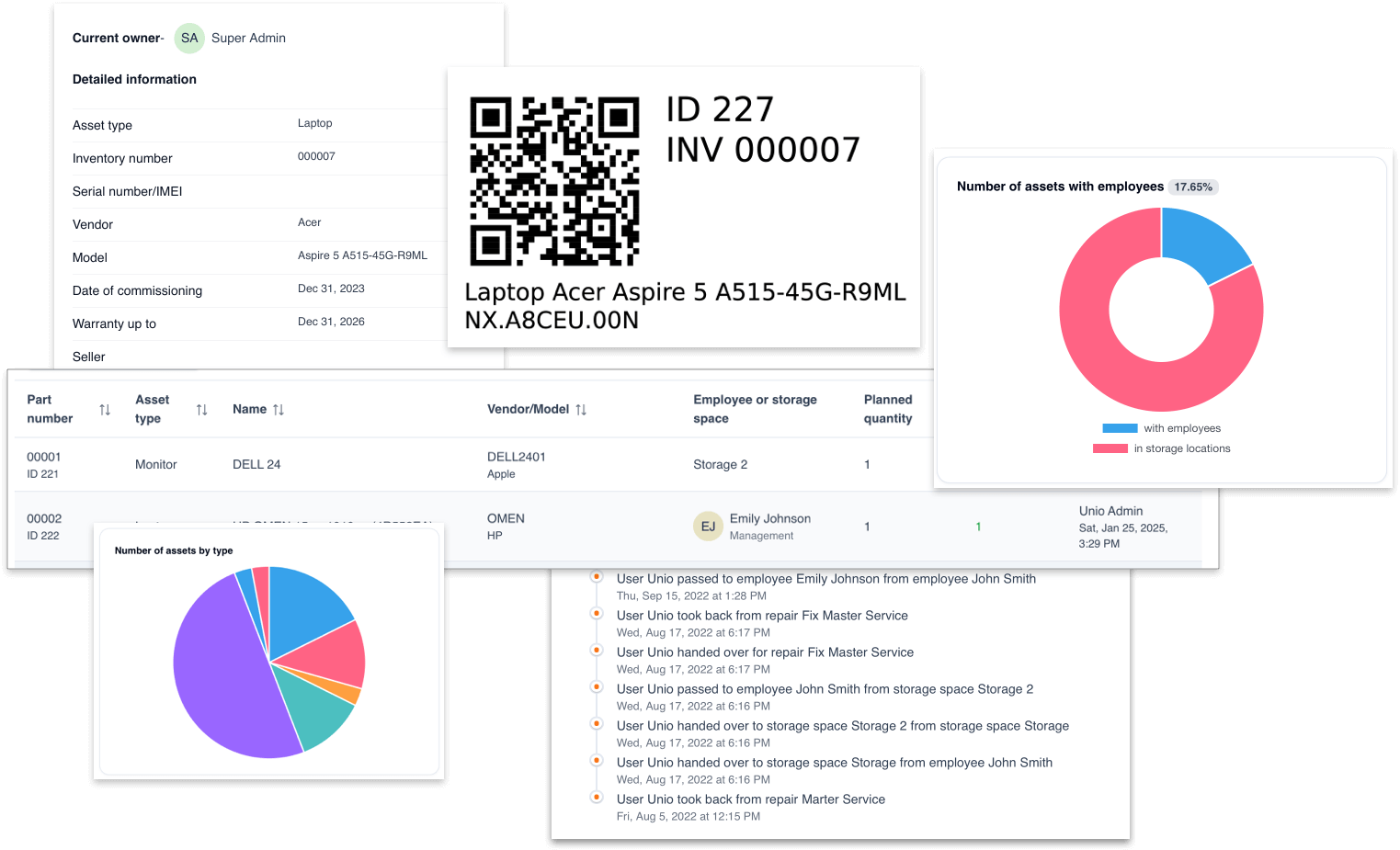

On job sites and production floors, equipment moves constantly — between shifts, teams, vehicles, and locations. UNIO24 shows where each item is right now, who used it last, and whether it’s available. QR/NFC tags make identification instant, while automatic movement logs prevent confusion, reduce theft, and give supervisors full visibility across all sites.

3. Reducing Losses, Theft, and Errors

Manual tracking doesn’t work in high-movement environments. UNIO24 eliminates errors by automating equipment logs and enabling smart labeling. Real-time tracking reduces lost and stolen tools, prevents double purchases, and helps teams maintain accountability. Departments and field crews all work with the same accurate data.

2. Maintenance & Service Scheduling

Heavy machinery, power tools, and industrial equipment require consistent maintenance to stay safe and productive. UNIO24 sends automatic reminders for inspections, lubrication, repairs, and safety checks. Each asset keeps a complete service history, helping organizations reduce downtime, avoid costly failures, extend equipment life, and stay compliant with safety standards.

4. Faster Inventory & Compliance Checks

Inventory checks across warehouses, vehicles, job sites, and production areas can drain days of work. With UNIO24, teams perform inventories directly from mobile apps using QR or NFC scanning. This speeds up audits by 40–70%, improves accuracy, and simplifies compliance documentation for safety inspections and operational reporting.

Benefits for Construction & Manufacturing

UNIO24 helps teams track assets, prevent equipment loss, manage maintenance, and speed up audits for safer, more efficient operations.

Fewer lost or stolen tools

Reduced downtime and repair costs

Clear visibility across job sites and departments

Better planning and equipment utilization

Faster safety and compliance reporting

Accurate budgeting and lifecycle management

Improved team accountability